How to Shortlist Wholesale Artificial Christmas Tree Suppliers for 2025 (EU, North America, Australia)

Planning your 2025 Christmas season means making decisions now. For importers, retailers, and distributors, a key decision involves which wholesale artificial Christmas tree suppliers, branch manufacturers, decoration factories, and wreath manufacturers make it onto your regional shortlist.

Lead times of 60–90 days, strict compliance rules in Europe, North America, and Australia, and rising logistics costs leave little margin for error. A structured way to rank Christmas tree suppliers, verify evidence, and run pilot orders is the safest path to a reliable assortment.

At Christmas Queen, we are a factory producer of artificial Christmas trees, branches, wreaths, and garlands. We support buyers in more than 36 countries with repeatable sourcing workflows. Below, we offer a practical framework you can adapt to your own supplier ranking and recommendation process.

If you would like an editable supplier scorecard, RFQ template, and sample checklist (XLS), you can request them from our team at sales04@christmas-queen.com or via WhatsApp: chat with Chloris.

Why Region Matters When Ranking Christmas Tree Suppliers

The region you import into significantly impacts your actual costs, lead times, and risk profile. When you build a shortlist of wholesale artificial Christmas tree suppliers, always look at three regional factors first: trade flows, lead times, and commercial conditions.

Trade Flows and Export Experience

Artificial trees and Christmas decorations are still heavily concentrated in Asia. Independent logistics data shows that China produces the majority of artificial trees and around 60% of global Christmas decorations and accessories. Consequently, for importers in Europe, North America, and Australia:

- Most reputable suppliers already ship regularly to your region.

- The best Christmas tree suppliers for Europe, North America, and Australia can show export records, packing photos, and customs documents for those destinations.

When evaluating potential partners, ask them to provide documentation for:

- Main export markets (EU states, UK, US, Canada, Australia, etc.).

- Typical INCOTERMS used (FOB, CIF, DDP) and preferred ports.

- Examples of past shipments similar to your order volume (e.g., 1–2 containers of pre‑lit PE trees to Germany or a mixed container of wreaths and garlands to the US).

Suppliers with demonstrated experience are better equipped to handle region-specific challenges like labeling, customs codes, fumigation, or packaging regulations.

Lead Times and Seasonal Planning

For new Christmas tree molds, new colors, or custom packaging, 60–90 days of production time is standard. On top of that, you must add:

- Sea transit time to your region.

- Seasonal port congestion.

- Any third‑party testing or inspections.

Importers typically find it safest to place pilot orders 4–6 months before the peak season. When you evaluate suppliers, confirm in writing:

- Standard lead time for repeat orders versus first orders.

- Cut‑off dates for Christmas 2025 production.

- Capacity for rush orders or reorders if a collection performs well.

This insight helps you rank suppliers not just by price, but by their realistic delivery capabilities.

Commercial Terms and True Landed Cost

The same FOB price from two different suppliers can lead to vastly different outcomes. Therefore, your supplier ranking should always account for:

- Willingness to quote indicative DDP prices into your market, not just FOB.

- Carton and pallet optimization (to minimize freight per unit).

- Experience with double‑layer corrugated cartons, corner protection, and palletization for sea freight.

Experienced suppliers, particularly those working with large retailers or importers, often provide standard carton sizes, tested stacking strength, and clear packing lists, which helps reduce your hidden costs. When you compare quotes, look for those details.

Regional Compliance Checkpoints: Europe, North America, Australia

Effective ranking of Christmas tree and wreath manufacturers is intrinsically linked to compliance. We provide practical regional checklists that you can directly integrate into your RFQs.

Europe (EU & UK)

For the EU and UK, chemical safety and packaging rules are non‑negotiable, especially for PVC and PE artificial Christmas trees, garlands, and decorations.

Key questions to ask include:

- REACH compliance for finished articles.

- Test reports for PVC/PE materials, especially phthalate content and heavy metals.

- Confirmation that inks, paints, flocking, and glitter meet relevant EU norms.

- Packaging that complies with EU packaging waste and recyclability requirements.

RFQ attachments to request:

- Latest REACH test report for comparable products.

- Material specification (PE/PVC grade, flame‑retardant additives if any).

- Sample photos or videos showing trees, branches, wreaths, and garlands out of carton.

- Draft packing list; for small parcels, CN22/CN23 where applicable.

This compliance rigor extends beyond just trees. When you evaluate recommendations for Christmas branch manufacturers, wreath manufacturers, and other Christmas decoration factories, the same REACH logic applies to all plastic and coated components.

North America (US & Canada)

In the US and Canada, electrical and labeling rules dominate the risk profile for pre‑lit products.

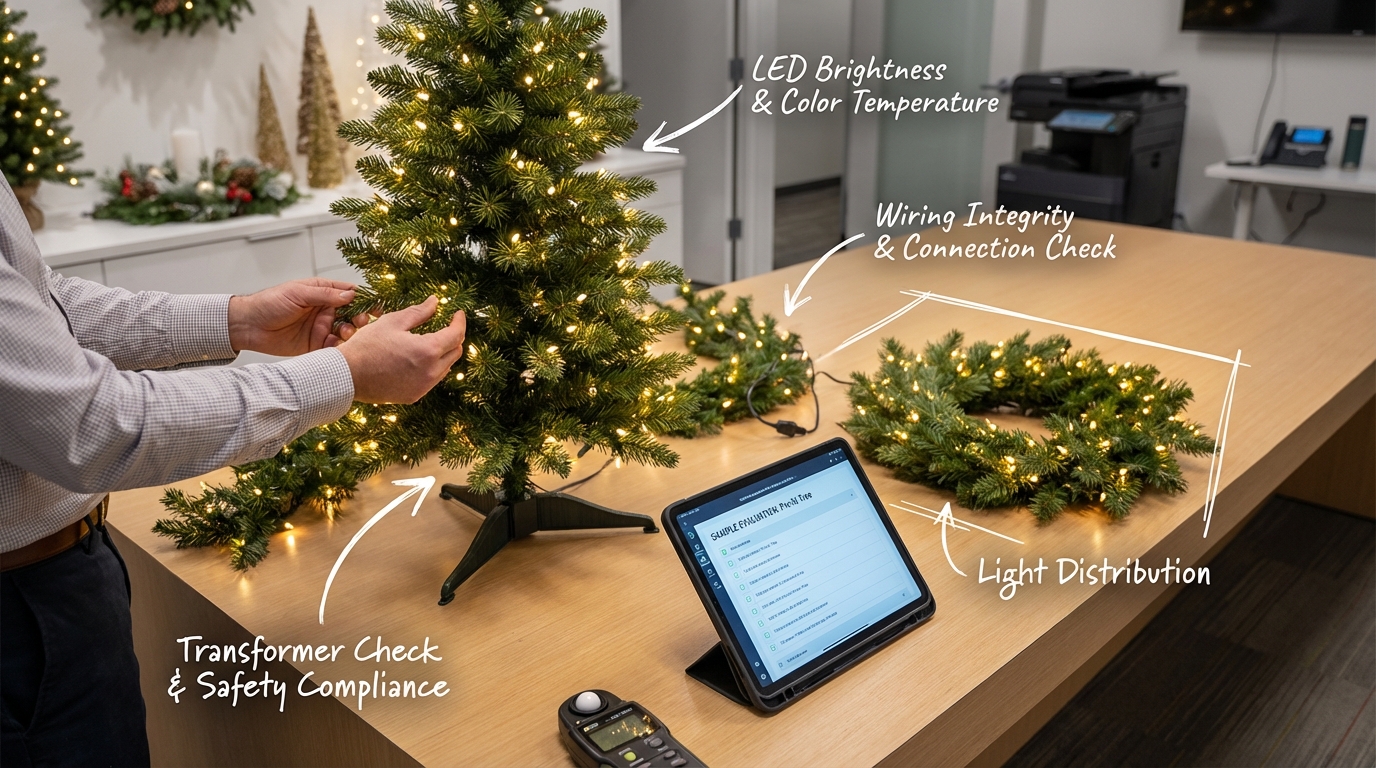

For any pre‑lit tree, LED branch, lighted garland, or illuminated wreath, confirm:

- UL, ETL, or CSA certification for the complete product or for key components (transformer, plug, light string).

- Wiring and transformer test reports, including over‑temperature and insulation resistance.

- Clear US/Canada labeling: voltage, wattage, warnings, country of origin, and indoor/outdoor rating.

RFQ attachments to request:

- Copies of UL/ETL/CSA certificates or accredited lab test reports.

- Wiring schematic and photos of connection points.

- Short product video of the lit tree or decoration during burn‑in testing.

Even for non-lit items like plain PE trees or wreaths, North American retailers are increasingly requesting flammability and chemical safety data, so it's wise to include these inquiries early.

Australia

The Australian market often aligns with EU and North American requirements, yet it has its own specific local approvals.

For importers targeting this region, check:

- Which electrical and consumer‑safety approvals your local importer will rely on (some accept EU or US reports with local documentation).

- Whether your supplier has shipped to Australia before and can show HS codes, commercial invoices, and packing lists used.

- Sea route and transit times to major ports such as Sydney, Melbourne, or Brisbane.

RFQ attachments to request:

- Copies of test reports accepted by existing Australian customers.

- Example commercial invoice and packing list.

- Declared HS codes for each product category (trees, branches, wreaths, garlands, small tabletop items, etc.).

Requesting all necessary certificates during the RFQ stage can prevent unexpected issues and help you quickly refine your list of recommended Christmas tree and decoration manufacturers.

Core Sourcing Checklist for Trees, Branches, Wreaths, and Garlands

Once basic regional fit is confirmed, move to product‑level checks. This is where you truly assess the quality of artificial Christmas tree manufacturers, branch suppliers, decoration factories, and wreath manufacturers.

Supplier Profile and Paperwork

For each candidate, ask for:

- Company profile and year of establishment.

- Factory photos (production lines, warehouses, packing areas).

- Export markets and reference customers (regions, not necessarily brand names).

- Product range by category: trees, branches, wreaths, garlands, small tabletop trees, mini sets, etc.

- Minimum order quantities and sample policy (fees, refund rules, lead time).

At Christmas Queen, as a manufacturer with over 5,000 SKUs and exports to more than 36 countries, we regularly support mixed containers across categories, which is ideal if you need cohesive assortments of trees, branches, and matching wreaths.

Product Quality Control Checklist

When inspecting samples, consider them your definitive reference standard. Typical checkpoints include:

- Raw Materials PE/PVC grade and surface finish. Material certificates or at least written declarations from upstream suppliers.

- Visual Appearance and Fullness Branch‑tip count and distribution. The 'fullness' of the tree, wreath, or garland after 30–90 minutes of fluffing, depending on its height and density. Color tone consistency across trees, branches, and wreaths in the same collection.

- Pre‑lit Safety and Performance (for trees, garlands, and decorative branches with lights) Flame and heat‑resistance behavior under testing. Transformer ratings and cable thickness. Quality of soldering, joints, and connectors.

- Surface Finishes Flocking adhesion (does “snow” stay on when gently shaken?). Color fastness in normal indoor light. UV resistance when products are sold as outdoor‑capable.

- Mechanical Strength Trunk and stand stability for medium and large trees. Hinge durability and bending cycles for branches. Pull tests on hanging points of wreaths and garlands.

For critical tests, many buyers use third‑party labs such as SGS or Bureau Veritas to verify materials and wiring. Reliable suppliers readily cooperate with this process; their willingness is a strong indicator when you're shortlisting and comparing Christmas tree suppliers across regions.

Packaging and Transit Simulation

Top recommendations for Christmas decoration manufacturers consistently highlight robust packaging. For seasonal categories, damage during sea freight can destroy margins.

Ask suppliers to explain and, ideally, show:

- Carton construction (e.g., double‑layer corrugated for export cartons).

- Palletization pattern, strapping, and corner protection.

- Box compression tests or internal standards (stacking height, weight per carton).

Include packaging criteria in your sample approval form, such as:

- Maximum acceptable tip loss on arrival.

- Acceptable number of broken branches or bent hinges per tree.

- Flex cycles tolerated by light strings during unpacking and re‑packing.

Building a Practical Supplier Scorecard

To streamline your selection from a broad list to a focused shortlist, many importers utilize a weighted scorecard. This method provides structure for ranking Christmas tree suppliers, branch manufacturers, and wreath factories.

Here's a typical weighting structure you can adapt:

- Product & Material Quality – 30%Consistency of materials, craftsmanship, realism of branches, fullness of trees, wreaths, and garlands.

- Certifications & Test Reports – 20%REACH, flammability, UL/ETL/CSA, other region‑specific approvals, and history of passing lab tests.

- Lead‑Time Reliability – 15%Ability to meet realistic production and shipping windows, plus flexibility for reorders.

- MOQ & Price Competitiveness – 15%Balance between cost, minimums, and assortment needs across trees, branches, wreaths, and other decorations.

- Packaging & Logistics Readiness – 10%Export‑ready cartons, pallet layouts, documentation quality, and shipping experience to your ports.

- After‑Sales & QC Cooperation – 10%Openness to third‑party inspections, claim‑handling process, responsiveness.

You can rate each supplier from 1–10 for every criterion:

- 8–10: preferred / low‑risk supplier.

- 5–7: acceptable with clear conditions or support.

- Below 5: high risk for that dimension.

Many buyers opt to shortlist only those suppliers scoring 7.5 or higher overall, or those excelling in at least three critical areas (typically quality, certifications, and lead time).

If you request our XLS scorecard template, you can easily input your own weights and automatically calculate rankings across various candidate suppliers.

Step‑by‑Step: RFQ → Sample → Pilot Order

A clear playbook ensures you evaluate artificial Christmas tree manufacturers, branch suppliers, and wreath manufacturers fairly and consistently.

1. RFQ: Capture All Critical Details

Your RFQ should define:

- Target products and categories (trees, branches, wreaths, garlands, tabletop minis, etc.).

- Material expectations: PE/PVC ratio, flocking, glitter, berries, pinecones, LED options.

- Regional compliance requirements (REACH, UL/ETL/CSA, local approvals for Australia).

- Preferred ports and INCOTERMS (FOB, CIF, DDP).

- Required documentation (test reports, certificates, packing specs, photos, and videos).

A well-defined RFQ simplifies the process of comparing and ranking Christmas decoration manufacturers on an equal footing.

2. Samples: Define What “Pass” Looks Like

From each shortlisted supplier, request:

- Physical samples of key SKUs (for example, one main tree size, a matching wreath, a garland, and a decorative branch from the same collection).

- Powered test samples for pre‑lit items, including transformers and plugs.

- The exact packaging that would be used for mass production.

Beforehand, agree on applicable lab tests (flammability, chemical, wiring, etc.) and determine cost responsibility for each scenario (new design vs. re-test of an existing certified design).

3. Virtual or On‑Site Factory Review

Before placing a substantial order, assess the factory's operational practices:

- Request a video walkthrough of production lines, warehouses, and packing stations.

- Check how molds, tooling, and decorations (berries, cones, glitter) are stored and labeled.

- Ask how repeat orders are tracked to maintain consistent appearance year after year.

If budget allows, consider a third‑party audit for your top 2–3 candidates.

4. Third‑Party Inspections and Lab Tests

Include the following in your plan:

- In‑process inspections (during assembly and packing) to catch issues early.

- Pre‑shipment inspections following AQL sampling standards.

- Independent lab tests for electrical components and materials where required.

Reputable suppliers will readily cooperate; their willingness is a strong indicator when you're shortlisting and comparing Christmas tree suppliers across regions.

5. Pilot Order and Scale‑Up

Before committing to your full seasonal volume, we recommend placing a pilot purchase order of 1–2 containers with each key supplier. For that pilot:

- Define clear QC checkpoints and communication channels.

- Agree on claim procedures (photo documentation, replacement policy, credit notes, etc.).

- Negotiate how sample fees are refunded once mass production starts.

Once the pilot arrives and performs well in your market, you can safely scale to larger volumes for Christmas 2025.

How Christmas Queen Supports Your Shortlist

At Shandong Christmas Queen Arts & Crafts Co., Ltd., as a factory producer of wholesale artificial Christmas trees and related decorations, we are specifically structured to support this evidence-driven approach.

For buyers building a shortlist of recommended Christmas tree, branch, decoration, and wreath manufacturers, here are our key strengths:

- Product Breadth: With over 5,000 SKUs covering trees, branches, wreaths, garlands, and small tabletop items, we enable coordinated collections.

- Export Coverage: We ship to over 36 countries, including EU states, the UK, North America, and Australia.

- Quality & QC: We maintain stable and reliable product quality through a comprehensive quality control system and strict production monitoring.

- Design Capability: Our continuous development ensures new styles and designs that follow international trends, from slim PE Christmas trees to mini tabletop trees with glitter and snow effects.

- Logistics: We use export-ready packaging with double-layer corrugated cartons and sea-ready palletization to protect goods in transit.

- Service: We offer responsive English communication, professional pre-sales and after-sales support, and a sample policy with refundable fees for mass orders (many in-stock items are free).

If your team is currently updating its ranking of Christmas tree suppliers and looking for new recommendations for Christmas branch, decoration, and wreath manufacturers, our team can share concrete case examples from different regions to demonstrate our capabilities.

Frequently Asked Questions from B2B Buyers

How long does it really take to fluff a tree for display?

Depending on height and branch density, expect 30–90 minutes of fluffing for a realistic full‑shape Christmas tree. Smaller tabletop trees and mini sets typically require less time.

Can you provide samples for trees, branches, wreaths, and garlands?

Yes. For most models, we provide samples; fees for custom items are refundable against mass orders, and many in‑stock models can be sampled for free. This helps buyers test complete collections of trees, branches, and matching wreaths or garlands before committing.

Which certifications are typically required for pre-lit trees?

For the EU, UK, US, Canada, and Australia, buyers typically look for:

- Electrical safety testing (often UL/ETL/CSA or equivalent lab reports).

- Flammability and chemical safety reports for materials.

- REACH compliance for EU shipments.

We work with independent labs and can support buyers who need to update or extend certification coverage.

What are typical minimum order quantities and lead times?

MOQ and lead time depend on the specific product (for example, a standard PE artificial tree, a heavily flocked branch, or a decorated wreath). As guidance:

- New production runs: 60–90 days from deposit to shipment.

- Repeats of established designs: often shorter, subject to material readiness and capacity.

- MOQs: flexible by category; mixed containers are possible for many buyers.

We recommend confirming per‑model MOQ and packing details during the RFQ stage, especially for new collections.

Can designs be customized for specific markets?

Yes. Buyers frequently request custom colors, flocking styles, glitter levels, berry and cone combinations, or unique garland and wreath designs for their private labels. Customization is usually available above a certain MOQ, which we will clarify during quotation.

How to Get Our 2025 Supplier Scorecard Pack

To simplify your sourcing process, our team offers a suite of practical tools for importers and retailers looking to shortlist Christmas tree suppliers and related manufacturers:

- Editable supplier scorecard (XLS) with weighted criteria.

- RFQ email templates covering trees, branches, wreaths, and garlands.

- Sample inspection checklist you can share with your own QC or third‑party inspectors.

You can request this comprehensive pack by contacting our team:

- Email: sales04@christmas-queen.com

- WhatsApp: chat with Chloris

- Phone: +86 132 8776 2672

Company address: No.659, West East Industrial Park, Dangjia Town, Shizhong District, Jinan, Shandong, China.

References

- Chengjing, J. (2013). Supplier selection based on AHP method: Supplier from China for Suomen Koristetuonti. Retrieved from Semantic Scholar database.

- The Chartered Institute of Logistics and Transport Singapore. (2024, February). CILT Buzz: Global logistics insights for the festive season.

- Innovation, Science and Economic Development Canada. (2025). Trademarks Journal (Class 26 & 28 entries on artificial wreaths, garlands and Christmas trees). Government of Canada.

- European Chemicals Agency. (2024). Guidance on requirements for substances in articles under REACH.

- UL Solutions. (2023). Holiday lighting and seasonal decorative products — safety and certification overview.

- Bureau Veritas Consumer Products Services. (2024). Best practices in quality assurance for seasonal decorative items.

- SGS. (2023). Flammability and chemical testing for artificial Christmas trees and decorations.

- Shandong Christmas Queen Arts & Crafts Co., Ltd. (2025). Product and export overview: Artificial Christmas trees, branches, wreaths and garlands.